AI-Powered Production Planning & Scheduling (PPS) for Smart Manufacturing

In today’s competitive market, smart manufacturing and AI-driven production scheduling have become essential for companies aiming to boost productivity, improve asset utilization, and deliver high-quality products on time. Our Production Planning and Scheduling (PPS) solutions ensure that orders are booked on available lines across multiple plants, processes, and equipment while considering capacity constraints and maximizing asset utilization.

Key Results for Smart Production Scheduling

Optimized Equipment Loading:

Ensure that all production equipment is used to its maximum potential through real-time capacity management and intelligent algorithms.Intelligent Sequencing:

Maximize production efficiency by sequencing operations based on material availability and production priorities.

Key Benefits of AI-Powered PPS for Manufacturing

On-Time, In-Full (OTIF) Delivery:

Ensure timely and accurate delivery to customers using AI-driven delivery commitment models and demand forecasting tools.Reduced Work-in-Progress (WIP) and Finished Goods (FG) Inventory:

Achieve a lean manufacturing approach with minimized WIP, optimizing storage costs and improving cash flow.

Order Priority Management – AI-powered scheduling ensures that high-priority orders are automatically allocated to available production resources, ensuring that the critical orders are delivered on time, regardless of other demands.

AI-Driven Delivery Forecasting

– Our delivery forecasting tools generate real-time delivery predictions for all open orders, considering capacity constraints, material availability, and production dynamics across plants.

Make-to-Order (MTO) and Make-to-Stock (MTS) Flexibility –

Our system supports both MTO and MTS orders, enabling you to define minimum and maximum inventory levels for MTS products and automatically generate orders based on stock levels and demand fluctuations. This enhances inventory management and streamlines production.

Constraint Management

Handle complex production constraints such as:

- Routing constraints

- Equipment loading and changeover times

- Manpower allocation

- Material availability

- Maintenance scheduling

- By automating constraint management, you improve production flexibility and reduce downtime.

Campaign Planning and Execution –

Plan and execute multi-machine campaigns using detailed batch processing rules, minimizing changeover times, reducing equipment downtime, and increasing throughput.

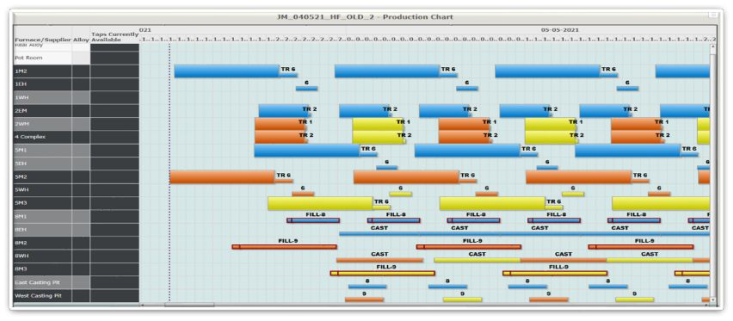

Integrated End-to-End Scheduling – Our end-to-end scheduling feature integrates all stages of production from procurement to final delivery, optimizing scheduling across the entire manufacturing process to ensure efficient resource use.

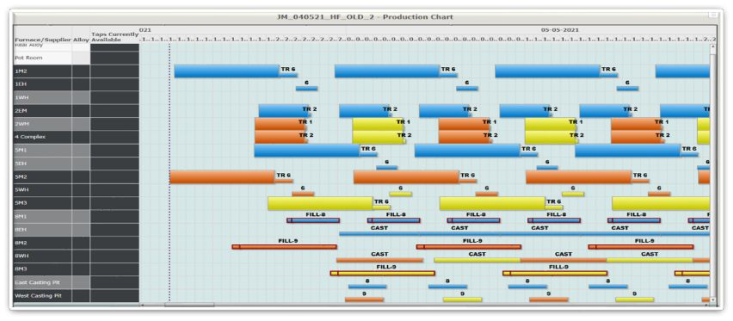

Comprehensive Schedule – Generate End-to-end Production schedule across all processes and stages one in step

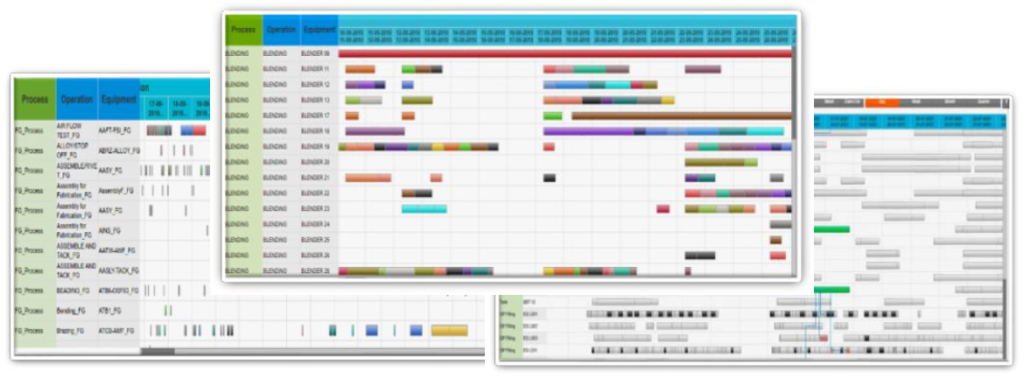

Production Sequencing – Optimize sequence for all equipment to maximize productivity and ensure timely delivery. Deal with multi-level BOM and sequence based on material availability

Optimal Capacity Utilization – Synchronize and balance capacities across stages and maximize asset utilization. Distribute load on equipment optimally based on capacity and constraints.

Multiple Factory Schedule – Deal with multi-factory scenarios where own factories are responsible for producing FGs and vendor factories are responsible for producing intermediates and key raw materials.

Get In Touch!

Drop us a line if you have any projects on your mind. Let’s discuss.

Contact Information

© 2025 Bluemingotech. All rights reserved.