Manufacturing Execution System (MES)

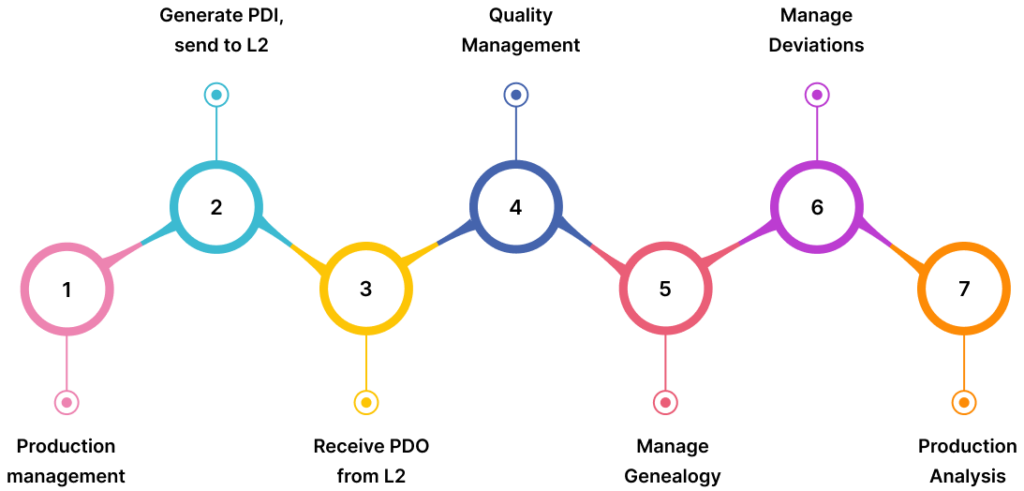

Track production and quality at all stages and gives full visibility of Order and Material Status. Integrate with Level 1 & 2 systems and helps in real-time production or quality decisions. Integrate with Plant specific detailed Schedulers

Key Results

- E2E automation for data capture

- Traceability and Genealogy

- Production Analysis

- Failure and breakdown prediction

Key Benefits

- Reduced WIP and Lead-time Real-time

- Manufacturing Visibility

- Reduced Quality Failures

- Reduced downtimes

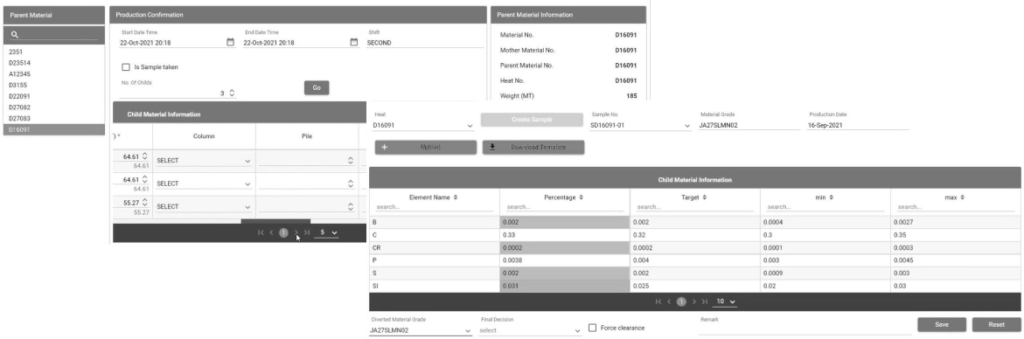

Track Genealogy – Track Genealogy from RM to IM to FG to track the source of the defect, identify Area of Improvement and resolve Customer Complaints. Generate FG numbers and tag to key RM batch numbers.

Shop-floor to Top-floor – Track Inventory, Order Progress Status, production defects, delays, stoppages, yield and production losses etc. and give visibility from Shop-floor to Top-floor.

E2E Integration – Integrate and download schedule and other Parameters to Level 1& 2 (CNC, HMI, SCADA etc.). Fetch & validate Actual Production Results (PDO) from Level 1 & 2. Manual Production Capturing Option in case of missing Level 1 & 2 Systems (like manual lines).

FG and WIP Inventory Management – Track production of WIP at each stage and generate real-time FG and WIP inventory record. Compute consumption of input materials at each stage using BOM and update WIP / RM Inventory

Quality Management – Capture and validate results, comments, specifications, recipes, and procedure documents. Provides real-time trends, statistics, and notifications to control quality levels. Generate Test certificates and quality documentation

Intelligence – Intelligent auto allocation and diversion to enable optimal shop floor decisions in real-time. Failure reduction by analyzing and improving operating parameters.

Machine Control – PDI generation for sequence and process instruction to the equipment

RM Inventory Control – Ability to define min and max levels for RM and generate RM orders based on Inventory position.

RM Inventory Management

- Generate MRP based on pending Orders, available Inventory in all forms, existing PR and PO etc.

- Consume RM at the lines based on FG and WIP production at each stage. Issue RM to lines on daily basis based on Production Schedule and inventory available at lines.

- Transfer materials from stores and track RM at the lines. Manage return of materials from lines back to stores based on quality issues, deviations, priority orders and changes in production sequence.

Get In Touch!

Drop us a line if you have any projects on your mind. Let’s discuss.

Contact Information

© 2025 Bluemingotech. All rights reserved.