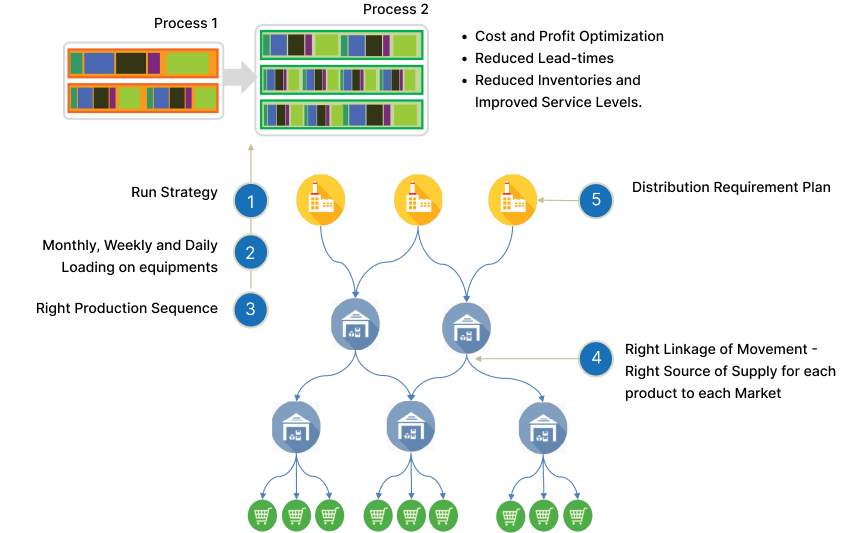

S&OP - Supply Planning

Unique Supply Planner is tightly integrated to detailed run strategy to ensure a very high degree of compliance between Plan and actual. It allocates date wise demand to factories based on freight and production costs and capacity constraints to generate or week wise production plan for each line.

- Optimal Demand Allocation – Allocates production to the right factory based on capacity constraints and total landed cost consisting of (a) Freight, (b) Landed Production Cost at own Factories and Third-Parties, (c) Tax benefits, Franchise Fees, Import and Export duties etc.

- Constraints – Constraints like Min and Max Load on Sites, Changeover Constraints, Capacity Constraints, etc.

- Alternate and Multi-Level BOM – Can handle Multi-Level BOM to create requirements of different intermediates and Raw Materials.

- Maximizes Capacity Utilization by optimizing Lot sizes and by optimal line selection, Optimizes Product Sequencing on the lines.

- Product Sequencing – Generates optimum production sequence on lines to ensure minimum inventory and waiting time.

- Multiple Planning Horizons – Generates daily, weekly or monthly production plan for factories and suppliers based on line capacities.

- Generates dispatch quantities from source to destination based on requirements, lead time, safety stock requirements, etc

- Generates Pre-build Plans ahead of Peak Seasons

Get In Touch!

Drop us a line if you have any projects on your mind. Let’s discuss.

Contact Information

© 2025 Bluemingotech. All rights reserved.